2023 Trends in Manufacturing

The manufacturing industry has always been a crucial component of the global economy. From producing essential goods to creating jobs, manufacturing plays a vital role in various sectors. The disruptions we witnessed throughout Covid and the subsequent product shortages we faced in stores throughout the nation made us all the more aware how vital the industry is to our everyday lives.

The dawn of new technologies and increasingly demanding consumer preferences have driven the industry towards significant changes. In this article, we’ll examine the top 2023 trends in manufacturing and how they will impact businesses in the sector.

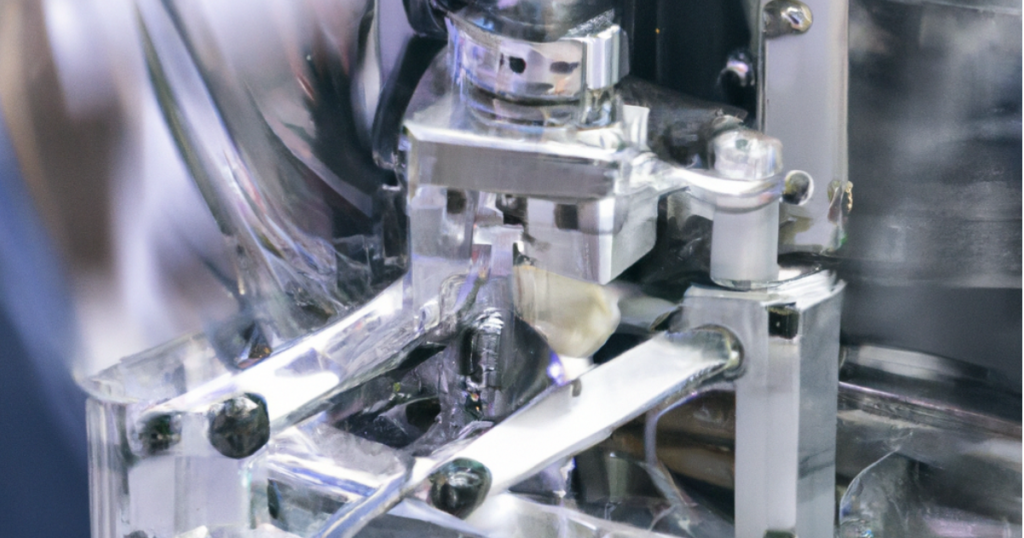

The Rise of Automation and Robotics

The manufacturing industry has been implementing automation and robotics for decades, but in 2023, we can expect to see a significant increase in their use. Here are some ways automation and robotics will impact manufacturing in 2023:

Increased Efficiency and Productivity

With automation and robotics, manufacturers can produce goods at a faster rate and with fewer errors. This increased efficiency and productivity can lead to cost savings and higher profits for businesses.

Improved Safety

Automation and robotics can also improve safety in the manufacturing industry by eliminating dangerous tasks that were previously done by humans. This will not only reduce the risk of workplace injuries but also increase the morale of workers.

The Emergence of Industry 4.0

Industry 4.0 is the next phase of the industrial revolution, characterized by the integration of smart technology and the internet of things (IoT) into manufacturing processes. Here are some ways Industry 4.0 will impact manufacturing in 2023:

Predictive Maintenance

By using IoT sensors and machine learning algorithms, manufacturers can predict when machinery will require maintenance, reducing downtime and saving costs.

Customization and Personalization

Industry 4.0 allows for greater customization and personalization of products, which can lead to increased customer satisfaction and loyalty.

The Growing Importance of Sustainability

In 2023, sustainability will be more critical than ever for manufacturers. Here are some ways sustainability will impact manufacturing in 2023:

Green Manufacturing

Manufacturers will increasingly focus on reducing their environmental impact through sustainable practices, such as using renewable energy sources and reducing waste.

Circular Economy

The circular economy model will become more prevalent in manufacturing, where products and materials are reused and recycled, reducing waste and conserving resources.

FAQs:

Q: What is the biggest trend in manufacturing for 2023?

A: The rise of automation and robotics is expected to be the most significant trend in manufacturing for 2023.

Q: How will Industry 4.0 impact manufacturing in 2023?

A: Industry 4.0 will impact manufacturing in 2023 by allowing for greater customization and personalization of products, as well as predictive maintenance using IoT sensors and machine learning algorithms.

Q: Why is sustainability important in manufacturing?

A: Sustainability is essential in manufacturing to reduce environmental impact, conserve resources, and meet the demands of customers who prioritize sustainable products.

Given the shortage of skilled labor and rising costs of shipping, taxes, fuel and goods, businesses must be creative to remain profitable. Integrating technological advancements offers a way for many to stay competitive while keeping up with growing demand.